The face of orthopedic care has changed dramatically over the years with the introduction of remarkable new implant technology to change the treatment of complex fractures and injuries to bones.

- As one of the innovative trends of these technologies, polyaxial locking plates present revolutionary appliances in modern orthopedic surgery, with their standing capabilities emerging to meet the precision and flexibility demands of the most complicated areas of fracture stabilization and improvement. This then allows better outcomes in patients of any age group and capability level.

- This article will guide you through the specific characteristics and uses of polyaxial locking plates, as well as how they are manufactured and what benefits accrue to using these plates—all this in full knowledge of their effects on health care from the perspective of the manufacturers who build the future of orthopedic technology.

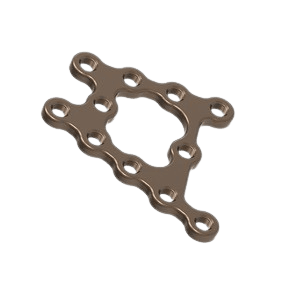

What Actually Are Polyaxial Locking Plates?

Polyaxial locking plates are state-of-the-art devices used in orthopedics. They are advanced constructs that help in achieving stabilization and provide structural support for bone healing periods in the process of fracture treatment.

Unlike the conventional plates that have fixed angles of screws for fixation, these implants allow for multidirectional screw placement, designed to approach the fracture according to the patient and the complexity of the fracture.

Key Features of Polyaxial Locking Plates

- Multi-Angular Screw Locking: Facilitates exact and flexible fixation.

- Anatomical Compatibility: Adapts to a wide range of bone structures and shapes.

- Minimized Periosteal Disruption: Maintaining Blood Supply, which is so critical for bone healing.

- Durability and Strength: Whereas they are built to be kept mechanically under huge stress.

These properties make polyaxial locking plates an invaluable treatment option for intra-articular complex fractures of the pelvis, shoulder, and ankle.

The Polyaxial Locking Plates Have Applications

They are like an A to Z approach or an indefinite asset for orthopedic assistance in managing any case.

- Trauma Surgery

High-Impact Trauma Polyaxial Locking Plates need high-energy trauma injury cases, with this providing stable fixation under very difficult injuries.

- Osteoporotic Fractures

In old patients with weakened bone structures, it provides secure stabilization, making ways for implant failure prevention.

- Reconstructive Surgery

Plating in congenital malformations and accidental deformities repair, exceedingly accurate.

- Pediatric Orthopedics

Such locking plates are meant to allow adaptability with growing bones hence can be highly effective in children.

- Sports Medicine

These plates can be most effective in fellow-oriented fracture stabilization, allowing athletes to get back to their feet quicker.

The Innovative Process of Manufacturing with Precision

Manufacturing polyaxial locking plates requires a unique endeavor of highly modern technology with high standard raw material selection and intense quality control all along the process. This, in turn, ensures that all the implants are conformed to the very strict demands of contemporary orthopedic treatment.

1. Material selection:

One of the most critical ones in exercising the function of an implant is the selection of material. Hence, manufacturers would commonly use:

Titanium alloys: These metals are lightweight, having biocompatibility, and corrosion activity-free.

2. Material choice is the most significant aspect in determining how well an implant works.

3. Design and Engineering Polyaxial locking plates are engineered with futuristic technology using:

CNC Machining: They are all about precision with very detailed.

3D Printing: This fast tracks prototyping with a room for customization.

4. Surface Treatments Special coatings give additional biocompatibility to the implant, ensuring a lower risk of infection prevalence, and provide better integration with the bone tissue.

5. Testing and Quality Assurance

Every implant is then subjected to rigorous testing to ensure that it complies with all international medical standards:

- Mechanical strength tests.

- Biocompatibility evaluations.

- Corrosion resistance tests.

Polyaxial Locking Plates Offer Many Advantages

These advantages make them very beneficial for both the surgeons and their patients.Due to this, polyaxial locking plates are one of the most preferred instruments in modern orthopedics.

- Higher precision in surgery

The surgeon may be required to use the variable-angle screw locking mechanism in adapting the fixation to the difficult fracture shape.

- Enhanced Bone Healing

These plates also ensure the continuity of periosteal blood flow, which leads to a natural healing environment.

- Range of Applications

Can be used for trauma, reconstructive, and pediatric surgery applications.

- Strong and Stable

These are meant to withstand the day-to-day mechanical stresses of movement and hold up over time reliably.

- Less Risk of Complications

This kind of locking avoids implant failure and screw loosening. Innovative Technology in Polyaxial Locking Plate. The field of orthopedic implants is improving every day, and companies are now coming up with better and innovative ideas to further enhance the utility of their polyaxial locking plates.

- Custom 3D-Printed Implants

Additive Manufacturing supports patient-specific designs which help in ensuring perfect fitment and minimize the wastage of material.

- Smart Implants

The real-time sensor incorporated in the implant could be utilized for bone-healing monitoring and may result in post-operative telemetry collection.

- Bioactive Coatings

Growth-factor-enriched coatings promise accelerated bone ingrowth and healing.

- AI-Driven Design

Artifice-based intelligence will optimally design the implants for better compatibility and performance with anatomy.

Manufacturing Sustainability

While the market for orthopedic implants is swelling, medicinal purposes emphasize the sustainable approach in processes:

Main Initiatives

Recyclable Materials: Source and use recycled metals such as titanium and stainless steel.

Energy Efficient Production: Machines and practices to save energy.

Waste Minimization: A new method adopted for adding material to construct minimum wastage.

In these trends, manufacturers not only reduce their environmental footprint but also enable them to exercise global matters of sustainability.

Patients Outcomes

Introduction of polyaxial locking plates is poised to revolutionize orthopedics care and improvement in most patient outcomes:

- Secured Fixation- The patients will have fewer complications due to both implant stability and durability.

- Rapid Recovery Time- Less tissue trauma with the advancement in bone healing allows faster rehabilitation.

- Mobility Restoration– Patients tend to regain their mobility levels faster, improving their lives.

- Fewer Revision Operations- Long term reliability of these plates reduces the scope for further surgical interventions.

Market Trends and Future Perspectives

The global market for polyaxial locking plates is increasing as a result of:

The aging population requiring superior attention from orthopedic surgeons and increased awareness and accessibility of safe and innovative surgical interventions.

Most prominent are:

Integration with regenerative medicine: For example the combination of implants with some biological healing therapies together will prove better for healing.

Affordable custom implants: a move toward converting personalized solutions into standard procedures in their cost.

Global: Wide distribution of access to world-class implants to the developing regions.

Manufacturers which put innovation, quality, and sustainability in priorities will be future leaders in this emerging market.

Conclusion

Polyaxial locking plates perfectly symbolize incredible advancement in implant technology for Orthopedics. The unique capacity of multi-angular fixation combined with long-term durability and biocompatibility makes these implants irreplaceable in today’s modern medicine.

The convenience of offering near trauma to pediatric and reconstructive surgery has managed to change patient outcomes regarding the provision of stability, precision, and much quicker recovery times. The challenge of manufacturers now rests in increasing the envelope of innovation while keeping affordability and sustainability.

As technology advances through its different cycles and as accessibility increases around the world, polyaxial locking plates will continue to redefine parameters in orthopedic care, serving as a cornerstone of innovation in contemporary medicine.

People also ask

Q1. What a polyaxial locking plate is?

Ans – Polyaxial locking plates are advanced technologies that enable multi-directional screw fixation to implants that help provide stability and flexibility in the treatment of complex fractures.

Q2. What is unique about them in the case of Ace Osteo?

Ans – They have state-of-the-art engineering and clinical compatibility in their construction and durability in their applications to allow their use in modern orthopedic care.

Q3. What materials are used in polyaxial locking plates by Ace Osteo?

Ans – Ace Osteo makes their polyaxial locking plates out of high-quality materials like titanium alloys and medical-grade stainless steel that are meant for performance durability and biocompatibility.

Q4. Polyaxial locking plates differ from conventional plates in what ways?

Ans – Polyaxial locking plates differ from conventional plates in that the angle is not fixed along the full length of the plate, whereas fixed-angle plates have a constant angle for all screws.

Q5. From which surgeries could one find use of polyaxial locking plates?

Ans – Depending on the types of trauma, such plates can be useful in major fractures, osteoporotic fractures, and complex reconstructive surgeries.

Q6. Why are polyaxial locking plates important in orthopedic treatment?

Ans – These implants increase stability, maintain healthy bone conditions, and add a high degree of precision in fracture fixation that is favorable for patient recovery.

Q7. Is there an option for custom polyaxial locking plate designs from Ace Osteo?

Ans – Yes, Ace Osteo tailors solutions specific to individual surgical requirements and employs advanced techniques like 3D design and prototyping.

Q8. What role do polyaxial locking plates play in trauma surgery?

Ans – These implants are meant to stabilize fractures in anatomically challenging areas, enabling secure fixation in an intently faster recovery for trauma patients.

Q9. What tests validate the quality of Ace Osteo’s implants?

Ans – Strongness, endurance, and biocompatibility tests are some of the important tests Ace Osteo carries out to meet international medical standards in quality check.

Q10. How does polyaxial locking provide surgical precision?

Ans – The multi-angular screw locking mechanism allows the fixation angle to be optimized and consequently provides precise and stable fracture repair.

Q11. What surface treatments are provided to the polyaxial plates from Ace Osteo?

Ans – Special coatings improve its corrosion resistance and improve integration of the implant in bone tissue.

Q12. Are poly axial Ace Osteo locking plates able to reduce surgical complications?

Ans – Yes, their design affects improving the incidence of screw loosening, implant failure, and many more postoperative complications.

Q13. What is the reason for leading Ace osteo in orthopedic implants?

Ans – Integrating high-grade materials with the latest technology and strict quality assurance makes Ace Osteo a reliable orthopedic solution.

Q14. Where can I get more information about Ace Osteo’s polyaxial locking plates?

Ans – You can check Ace Osteo’s website to have more information regarding polyaxial locking plates or any of its products.