Introduction

Bone plates are among the most vital medical implants that are used to stabilize and support fractured bones during the healing process. Choosing the right medical implant manufacturer can have an impact on both the success of the surgery and the long-term recovery of the patient. Manufacturers of bone plates are responsible for designing, testing, and producing implants that must lie under international safety standards, mechanical durability, and biocompatibility protocols.

Ace Osteomedica, a leading medical implant manufacturers has consistently emerged as a trusted and innovative manufacturer of bone plates. Key factors that should be considered by bone manufacturers are quality of the material, product range and specialization, compliances and certifications, innovation and R&D, customization and feedback of surgeons, and global distribution. All these factors affect the credibility and reliability of medical implant manufacturers.

In simpler words, Manufacturers of bone plates are not just suppliers, they are also partners in patient’s recovery and surgical success. Ace Osteomedica’s track record, dedication to innovation, and commitment to quality standards make it a trusted choice for orthopedic professionals.

Bone plates are essential tools in orthopedic surgery. A successful implant depends on both surgical technique and the medical implant manufacturers. Whether treating fractures or complex reconstructive procedures, success depends on the above-mentioned things. With the increase in trauma cases and orthopedic surgeries, the need for trusted and innovative manufacturers of bone plates is more critical than ever.

What are Bone Plates?

Bone plates are implants that are used in orthopedic surgeries to stabilize fractured bones. These plates are metallic or bio-compatible devices designed to hold broken bone fragments together in a fixed position. The plates are made from stainless steel or titanium, generally known for their strength, corrosion resistance, and compatibility with the human body. In some cases, materials that can be dissolved in the body over time are also used, such as bioabsorbable materials.

Bone plates are cautiously designed to conform to the contours of various bones in the human body. These plates are fixed directly onto the surface of the bone with the use of orthopedic screws, which might or might not lock into the plate, depending on the type of implant used. After fixing, these plates hold the bone fragments in accurate anatomical alignment and neutralize mechanical forces such as tension, compression, and torsion that would impede the healing process.

The size of bone plate screws varies based on:

- The location of the fracture

- The bone type involved (long bone, flat bone, irregular bone)

- The kind of fracture (simple, comminuted, oblique, spiral)

- The movement and load that bone usually experiences

Some common types of bone plates are:

- Dynamic Compression Plates (DCP): These are designed for applying controlled compression at the fracture site during screw insertion. This helps in promoting direct bone healing and reduces the healing time.

- Locking Compression Plates (LCP): Combines the advantages of conventional plating and locking screw technology. The screws provide an angular stable construct that is useful in osteoporotic or comminuted fractures. LCPs minimize periosteal damage reducing the need for plate-to-bone contact.

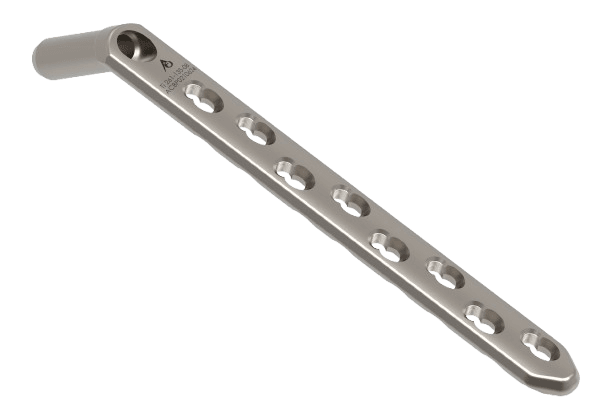

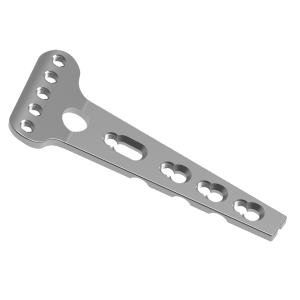

- T-Plates and L-Plates: To match specific bones, these plates are anatomically shaped. They are used for periarticular fractures. The T or L shape enhances the stability in complex fractures.

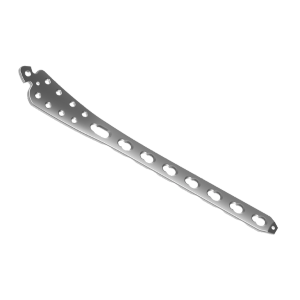

- Reconstruction Plates: These plates are contoured and flexible which makes them ideal for pelvic, clavicle, and facial fractures. They can be bent in multiple planes to match the bone surface which is important in irregular anatomical areas.

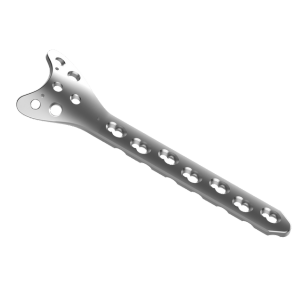

- Clavicle Plates and Distal Radius Plates: These plates are pre-contoured for anatomical areas like the clavicle or wrist. To match the natural S-shape of the bone, clavicle plates often have a curvature.

- Variable Angle Plates: Variable Angle Plates (VAPs) are advanced orthopedic implants designed for stable fixation of bone fractures, especially in complex and osteoporotic cases. Unlike traditional locking plates that restrict screw placement to fixed trajectories, VAPs allow multidirectional screw angulation, typically within a ±15° cone, improving adaptability to patient anatomy.

Why Choosing the Right Bone Plate Manufactures Matters

All medical implants are not manufactured equally. A bone plate is effective and the effectiveness lies in its material quality, biochemical design, precision engineering, and compatibility with human anatomy. All these aspects are influenced by the capabilities of the manufacturer. Leading medical implant manufacturers like Ace Osteomedica ensure that:

- Their materials are biocompatible and free from corrosion.

- The plates are shaped and contoured for optimal anatomical fit.

- Rigorous quality checks are included.

- Clinical research and surgeon feedback.

Factors to Consider When Selecting a Bone Plate Manufacturer

- Material Excellence – This is one of the most important features of bone plates. Preferred materials are high-grade stainless steel and titanium alloys are preferred because of their strength and biocompatibility.

- Technological Innovation – The demand for advanced implant design is there in modern orthopedics. medical implant manufacturers must invest in R&D which will improve features like plate thickness, hole patterns, flexibility, and screw-locking mechanisms.

- Precision Engineering – Ace Osteomedica uses CNC machinery, laser cutting, and robotic polishing, ensuring unmatched accuracy in every bone plate.

- Customizability and Surgeon Collaboration – Every fracture is different so surgeons require implants tailored to the patient’s specific needs. Ace Osteomedica provides custom implant solutions by collaborating with orthopedic surgeons.

- Regulatory Compliance – The medical implant manufacturers complies with ISO 13485, CE Marking, and other relevant international certifications.

- Wide Product Range – Ace Osteomedica provides an extensive lineup of bone plates from trauma and reconstruction to pediatric orthopedics.

- Cost Effectiveness – A balance between affordability and premium quality should be maintained so that the implant stays cost-effective without compromise.

What sets Ace Osteomedica apart is its international quality standards with deep local market understanding, strong distribution networks, and sustainable practices in this production process.

Conclusion

When picking a bone plate, you are choosing more than just a product. The right medical implant is a promise of healing and can accelerate recovery, reduce complications, and restore mobility. These are the reasons why selecting the right bone plate manufacturers is an important decision. With a commitment and legacy built on precision, quality, and innovation, Ace Osteomedica, stands out as a leading reliable orthopedic implant manufacturer worldwide.