Top Bone Screw Suppliers in India

India has established itself as a world leader in the suppliers of bone screws in india. These are implant devices used in surgery as supportive hardware, offering stability to damaged and fractured bones. With numerous suppliers focusing on quality, innovation, and international standards compliance, India stands as the hub for almost everything orthopedic. Following is a list of the 10 best suppliers of bone screws in India who are credited and acknowledged for their reliable and trustworthy production.

2. ACE Osteomedica

Suppliers Of Bone Screws In India ACE Osteomedica is a pride in the field of orthopedic implants suppliers, boasting specialization. They produce high-precision screws that take care of most orthopedic needs, ensuring high performance and safety for patients. ACE Osteomedica applies sophisticated technology and stringent quality checks at every stage of production. Their focus on innovation and affordability has made them a favorite with surgeons and hospitals across India. With their dedication to quality, they ensure adherence to international standards, making them great leaders in the industry.

-

Niche Products

Suppliers Of Bone Screws In India ACE Osteomedica is a one-stop destination for all products directed towards bone and joint interventions. Their range include bone screws and plates, cannulated screws, and any other advanced implant which fulfills all the necessary conditions of precision and durability. Each product is supplied with medical-grade materials like stainless steel and titanium.

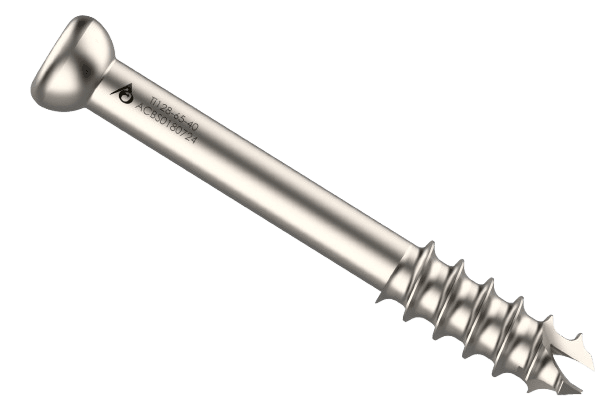

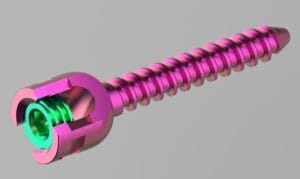

Among their product range is the cannulated screw, which has some specific indications during orthopedic surgeries for fracture reduction. Available in various sizes, these screws have features for disease processes like maximum stability and are best for minimally invasive procedures, thereby improving recovery for patients.

-

Quality Commitment and Standard Compliance

The products meet international certifications such as ISO 13485 and CE marking, as ACE Osteomedica works by narrow quality standards. Advanced investment in research and development has put the company ahead of time, bringing innovative products from its R&D to meet the changing needs of medicine.

All these activities make sure that good technology and maximum testing support a production process that is highly reliable and performs well. Safety also covers the implants or instruments that need to be sterile and secure through transport and usage.

-

Serving Healthcare Professionals Worldwide

Suppliers Of Bone Screws In India ACE Osteomedica is not merely a supplier; it is a partner in creating healthcare excellence. They can boast that their products are trusted by patients and healthcare institutions across the globe because of their precision engineering and unmatched performance. The company has a vision of improving patient outcomes through the provision of best quality possible medical tools to practitioners.

1. Siora Surgicals Pvt. Ltd.

Siora Surgicals is a trailblazer in the field of orthopedic implants, having established itself in the industry for over three decades. The company boasts an extensive portfolio of bone screws, plates, and other implants. With international accreditations like ISO 13485 and CE, Siora Surgicals ensures that their products reach the highest international quality standards. Their modern factories and strong R&D have made Siora a name on the global market, exporting to more than 40 countries.

3. GPC Medical Pvt Ltd.

GPC Medical is an internationally known supplier and exporter of orthopedic implants, of which bone screws are included. It caters to over 120-plus countries with a vast range of products certified on international certification, CE, and ISO. Bone screws by GPC Medical are made from high-grade stainless steel and titanium, making them reliable and robust. Indeed, the customer friendliness and competitive pricing have led to GPC Medical being a popular choice among healthcare providers across the globe.

4. Hindustan Surgical

In the Indian market of orthopedic implants Hindustan Surgical has played a major role. The company is also known for its whole range of Suppliers of cranio maxillo for all possible surgical applications. Hindustan Surgical always believes in quality control and technically engineered innovative products that are at par with International standards. The focus of Hindustan Surgical on affordability and efficiency has won the hearts of a residual customers’ basket.

5. Narang Medical Limited

Suppliers Of Bone Screws In India Narang Medical is one of India’s biggest suppliers and exporters of orthopedic implants as well as other medical equipment. Its bone screws are highly regarded for having the best quality and precision. Products from Narang Medical are supplied under the strictest quality control measures to ensure that items have the standard of safety and reliability. With a major emphasis on customer satisfaction, the company is determined to continuously introduce innovations in products.

6. Bio Med Healthtech Pvt. Ltd.

Suppliers Of Bone Screws In India Bio Med Healthtech is a reputed name in orthopedic implants and has a wide array of products, including bone screws. These are specifically made bone screws for surgeons’ and patients’ very unique needs. The company invests in research and development to remain competitive in the market by ensuring that its innovations are not only creative but affordable.

7. Unimax Medical Equipment Pvt. Ltd

Suppliers Of Bone Screws In India Unimax Medical is a reputed maker of orthopedic implants such as bone screws. It has been around long enough to know how to make these products from the experience gained. In-state use only focused on precision engineering and vigorous quality control to produce reliable and effective products that have developed into a preferred choice of healthcare professionals.

8. Kaushik Orthopaedic Pvt. Ltd.

Another name that shines brightly in the Indian orthopedic market is Kaushik Orthopaedic. The company supplies a wide range of bone screws that are strong, accurate, and meet international standards. The main reason why they have earned a reputation and showcased goodwill from the hospitals and clinics of the country is their promise of quality and affordability.

9. Dolphin Surgeons

Suppliers Of Bone Screws In India Dolphin Surgicals is emerging as a supplier mainly into orthopedic implants and instruments. Bone screw supplying includes high-quality and the most innovative designs. Heavy investment into research and development puts into operation their products according to the changing needs of the medical community. This organization is known for reliability and affordability due to its commitment to excellence.

10. Ortho Care Surgicals Private Limited

Suppliers Of Bone Screws In India Ortho Care Surgicals is a name people trust for orthopedic implants and subsequently a range of bone screws being produced. The company mainly channels in obtaining raw materials, which are high-quality raw materials and advanced manufacturing techniques to deliver products in harmony with international standards. From a concerned attitude in customer satisfaction along with product improvement, Ortho Care Surgicals stands firm to compete in the market.

Quality Standards for Bone Screws in India - Suppliers Of Bone Screws In India

In orthopaedic treatment procedures, bone screws are associated with medical devices used for fixing and stabilizing bones during the healing process. Bone screw quality is important in terms of successful surgical outcomes, patient safety, and long-term durability. In India, the suppliers strictly follow the quality specifications to serve the demands from domestic and international markets. This article elaborates on the key quality standards, certifications, and factors that keep the bone screws supplied in India reliable.

1. International Certifications for Bone Screws

Suppliers of bone screws in India try to strengthen the trust and credibility associated with their products by abiding by international certifications most relevant to their customers: ISO 13485: Is a certification that states that the supplier had a sound quality management system (QMS) with respect to the medical device industry. This is largely with regulatory compliance, risk management, and product consistency in mind.

CE Certification: A CE mark indicates that the bone screws comply with all health, safety, and environmental protection standards necessary for sale in the European Economic Area (EEA). FDA Approval: A vital step for the exporting companies in the United States, FDA approval helps prove that the products meet U.S. safety and performance standards.

2. Materials Used in Bone Screw supplying

The material quality used in bone screws significantly influences their performance. Bone screws supplied in India, for instance, include these common materials.

- Stainless Steel: It possesses high corrosion resistance and durability and is biocompatible, making it ideal for long-term implantation.

- Titanium and Titanium Alloys: They are lightweight, very strong, and have very high biocompatibility. Titanium is really used because of its excellent osseointegration properties.

Well-defined design and supplying standards for Indian suppliers include:

- Precision Engineering: The computerized precision-controlling machinery can dimension and thread bone screws for optimum functioning.

- Biocompatibility Testing: Screws are subjected to extensive testing, making sure that the insertions into the human body do not result in bad effects.

- Sterilization: Bone screws undergo processes like gamma irradiation or ethylene oxide for method sterilization.

3. Quality Control and Inspection

Production goes under stringent quality processes at each level to make sure the highest standards are adopted. Some of these are:

- Inspection of Raw Materials: All materials are tested on strength, purity, and biocompatibility before production.

- In-process Quality Checks: All stages of supplying are attended with inspection in order to ensure no variance in dimensions, surface finish, and threading.

- Final Product Testing: The mechanical testing of bone screws consists of tensile, torsion, and fatigue tests in order to establish their reliability.

Regulatory Requirements in India

The medical devices industry in India is controlled by the Central Drugs Standard Control Organization (CDSCO) under the Medical Device Rules, 2017. Bone screws fall under the definition of medical devices and therefore require suppliers to obtain the following:

- Supplying License: Issued after thorough inspection of the facility, processes, and documentation.

- Quality Audits: Regular audits ensure that the unit complies with the standards of both Indian and international importance.

Key Players Upholding Quality Standards Several

Renowned Indian Suppliers for Commitment towards Quality include Siora Surgicals Pvt Ltd. International Certification Bone Screws as per ISO and CE Compliance.

Suppliers of Bone Screws in India: ACE Osteomedica specializes in high-precision engineered screws, all complying with the global expectations of biocompatibility and durability.

GPC Medical Ltd : Screws of international compliance quality, high tested

9. Challenges of Quality Assurance

Suppliers today are burdened with:

- Expensive: To meet international quality standards, suppliers inevitably invest a lot of resources in testing equipment, machines, and certification processes.

- Trained Manpower: Ensuring proper availability of trained manpower for precision engineering and quality control operations.

- Global Competition: Compete with costs against already present established global suppliers.

10. Future of Quality Standards in India

Rapid evolution of India’s orthopedic implants industry with an increasing inclination towards innovation and conformity to global standards. Future trends will include:

- Adoption of Smart supplying: implementing IoT and AI in real-time quality monitoring and process optimization.

- Focusing on Exports: Improving quality standards so that the international marketplace demands can be met.

- Collaboration with Research Institutes: Medical research organizations engage for future development of next-generation implants.

Comparison of Leading Bone Screw Suppliers in India - Suppliers Of Bone Screws In India

Company |

Product Range |

Quality Standards |

Pricing |

Global Presence |

USP |

| Siora Surgicals | Comprehensive implants | ISO, CE | Competitive | 40+ countries | Extensive R&D and precision products |

| ACE Osteomedica | High-precision screws | ISO, CE | Affordable | Growing | Cutting-edge technology |

| GPC Medical | Extensive portfolio | ISO, CE | Moderate | 120+ countries | Customer-centric approach |

| Hindustan Surgical | Diverse product range | CDSCO | Budget-friendly | Emerging | Affordable solutions |

| Narang Medical | Wide variety | ISO | Competitive | Asia, Europe, Africa | Reliable customer support |

| Bio Med Healthtech | Advanced materials | ISO 13485 | Premium | Growing | Innovation and customization |

| Unimax Medical | Standard screws | ISO | Highly affordable | Limited | Cost-effective solutions |

| Kaushik Orthopaedic | Comprehensive range | ISO, CE | Affordable | Emerging | Customer satisfaction focus |

| Dolphin Surgicals | Basic to advanced screws | ISO | Moderate | Limited | Durable and long-lasting products |

| Ortho Care Surgicals | Standard and customized | CDSCO, ISO | Competitive | Growing | Surgeon-specific solutions |

Siora Surgicals Pvt Ltd.

- Product Range: Siora Surgicals brings out a wide range of orthopedic implants, from cortical, cancellous, and locking screws.

- Quality Standards: ISO 13485 and CE certified, fulfilling all international regulations in terms of quality.

- Pricing: Competitive in all price ranges, mainly focusing on affordability.

- Global Presence: Exported to more than 40 countries in reputation worldwide.

- Unique Selling Point (USP): Excellent R&D and a great reputation in precision-engineered products.

ACE Osteomedica

- Product Range: It deals specifically with high-precision bone screws for different orthopedic uses.

- Quality Standards: It complies with ISO 13485 and CE certifications for all its products.

- Pricing: Provides a very reasonable price range and high-value offerings.

- Global Presence: Emerging presence both in local and international markets.

- USP: Importing the latest technology and rigorous quality checks that superiorly perform their products.

GPC Medical Ltd.

- Product Range: Provides a huge selection of orthopedic screws, which includes locking, cannulated, and suppliers of bone plates.

- Quality Standards: With ISO 13485 and CE certification, the high-quality consideration matters.

- Pricing: Prices are moderate, and there’s an option for a mixture of budgets.

- Global Presence: Export to more than 120 countries, along with Europe and Africa.

- USP: Customer focus with an eye for sustainability and eco-friendly supplying processes.

Hindustan Surgery

- Product Range: Suppliers of bone screws self-tapping and specialty screws for specific surgical applications.

- Quality Standards: In compliance with CDSCO and maintains good standards.

- Pricing: Best in economy without losing quality.

- Global presence: Domestic strong with growing exports.

- USP: Low-cost solutions for even small clinics and hospitals.

Narang Medical Limited

- Product Range: The widest range of orthopedic implants, including locking screws and cannulated screws.

- Quality Standards: ISO-certified and complying with international standards.

- Pricing: Reasonably priced and offers bulk purchase discounts.

- Global Presence: Companies exporting their finished products to most regions across Asia, Europe, and Africa.

- USP: Massive product variety and reliable customer support services.

Bio Med Healthtech Pvt. Ltd.

- Product Range: Focuses on titanium and stainless steel bone screws for different orthopedic surgeries.

- Quality Standards: Adheres to International Standards in compliance with ISO 13485.

- Pricing: Price tag carrying slightly higher due to advanced product features.

- Global Presence: Strong domestic sales and gradually increasing international footprint.

- USP: Emphasis on innovation and customized defining solutions to surgeons.

Unimax Medical Equipment Ltd.

- Product Range: Regular bone screws used for general applicability on orthopedic procedures.

- Quality Standards: ISO certified and complies with other regulatory certifications.

- Pricing: Very affordable, targeting small healthcare facilities.

- Global Presence: Limited but growing steadily across the world.

- USP: Cost-effective solutions to basic orthopedic needs.

Kaushik Orthopaedic Pvt. Ltd.

- Product Range: Supplying broad range screws, including cortical and cancellous screws, among others

- Quality Constraints: Since products are supposed to comply with international standard requirements, all products are ISO and CE certified.

- Price: Affordable price but price flexible for huge orders.

- Global Presence: New emerging player in the export market.

- USP: Reliable quality focused on customer satisfaction.

Dolphin Surgical Products

- Product Range: Bone screws with their various forms, from simple to complex, and other orthopedic instruments.

- Quality Standards: Well certified in ISO with a lot of emphasis on biocompatibility.

- Pricing: Fairly affordable and gives value for money.

- Global Presence: Limited international market but good presence within the country.

- USP: Durability and long-lasting orthopedic implants.

Ortho Care Surgicals Pvt. Ltd.

- Product Range: Supply readymade as well as customized bone screws for orthopedic surgeries.

- Quality Standards: As per CDSCO and international norms.

- Pricing: Competitive and custom pricing.

- Global Presence: Domestic leader with improved export sales to neighboring countries.

- USP: Solution of product customization and surgeon specificity highlighted.

Regulatory Requirements for Suppliers of Bone Screws in India -

Suppliers Of Bone Screws In India has emerged as an important hub for surgical products like bone screws, as it has put in place a regulatory framework that governs these suppliers to ensure the safety, quality, and efficacy of this critical orthopedic product. Failure to comply with the regulations will spell doom both in the domestic and overseas markets. The guideline summarizes key requirements and processes for suppliers of bone screws in India for compliance.

- Classifying Bone Screws

It is essential for bone screw suppliers based in India to classify their products into the following categories to determine the regulatory pathway:

- Class B (Low-Moderate Risk): Basic orthopedic screws.

- Class C (Moderate-High Risk): Advanced screws including locking and cannulated screws.

Based on this, licenses will differ in number, as well as from one regulatory path to another, hence the number and type of tests or approvals required.

- Regulatory Oversights by CDSCO

These authorities include the Central Drugs Standard Control Organization (CDSCO) under the Ministry of Health and Family Welfare of the Government of India, which regulates the import, supply, and sale of medical devices and equipment such as bone screws in India. All suppliers of bone screws in India have to abide by the Medical Device Rules, 2017.

3. Licensing and Registration Requirements

Bone screw suppliers in India need to:

- Register the device at the CDSCO portal for Class C ones.

- Obtain a supplying license from the appropriate State Licensing Authority (SLA) through CDSCO processes and protocols.

- Licensing assures that the supplying facility meets the requisite regulatory and quality standards.

4. ISO 13485 Certification

ISO 13485 is an obligatory certification for bone screw suppliers in India. It is mainly aimed at effective Quality Management System (QMS) establishment for medical device purposes. Some of the key advantages include:

- Streamlining processes for supplying

- Enhancing product safety and reliability

- Making products acceptable in the global market.

5. Standards Compliant to BIS

The Bureau of Indian Standards (BIS) has mentioned appropriate technological standards these devices should comply with. Bone screw ssuppliers in India should adhere to these standards and not compromise on safety and performance.

6. Clinical Evaluation and Testing

Class C bone screws will require clinical trials to prove efficacy and safety. Bone screw suppliers in India should:

- Conduct their trials according to Good Clinical Practice (GCP)

- File the said data to the CDSCO for approval.

- This will ensure that products are in tandem with both local acceptance and global approval.

7. Post-Market Surveillance

License-granting processes are over; even suppliers of bone screws in India have to keep an eye on their post-market surveillance activity. This includes:

- Keeping an eye on all adverse events relating to their products;

- Product recalls where applicable.

- Continuous monitoring assures the long-term safety of bone screws whilst being deployed in surgeries.

8. Packaging and Labeling Regulations

Proper labeling is essential to meet the New Norms in India and to the suppliers of Bone Screws. Labels Must Include:

- Manufacture name and address; batch number, date of manufacture, and expiry.

- Instructions for use with safety warnings.

- Correct labeling will not only ensure conformity but also provide confidence among healthcare providers.

9. Exports and Global Compliance

Most suppliers of bone screws in India purport to target the international markets. Compliance with the international standards, namely CE marking or that of the U.S. FDA, is vital for exports. This implies adhering to stricter guidelines, such as product testing and quality documentation.

10. Issues faced by Indian suppliers

There are certain things in common, such as:

- The high cost of certifications and clinical trials.

- Most of the regulatory requirements are complicated and change often.

- Limited awareness of global compliance standards.

Addressing these challenges becomes essential to ensure market competitiveness and market growth.

CANNULATED SCREW 7.0MM X 16MM THREAD

Model |

Length |

S.S (Stainless Steel) |

Titanium |

| Cannulated Screw 7.0mm x 16mm | 40mm | 031-70-40 | Ti031-70-40 |

| Cannulated Screw 7.0mm x 16mm | 45mm | 031-70-45 | Ti031-70-45 |

| Cannulated Screw 7.0mm x 16mm | 50mm | 031-70-50 | Ti031-70-50 |

| Cannulated Screw 7.0mm x 16mm | 55mm | 031-70-55 | Ti031-70-55 |

| Cannulated Screw 7.0mm x 16mm | 60mm | 031-70-60 | Ti031-70-60 |

| Cannulated Screw 7.0mm x 16mm | 65mm | 031-70-65 | Ti031-70-65 |

| Cannulated Screw 7.0mm x 16mm | 70mm | 031-70-70 | Ti031-70-70 |

| Cannulated Screw 7.0mm x 16mm | 75mm | 031-70-75 | Ti031-70-75 |

| Cannulated Screw 7.0mm x 16mm | 80mm | 031-70-80 | Ti031-70-80 |

| Cannulated Screw 7.0mm x 16mm | 85mm | 031-70-85 | Ti031-70-85 |

| Cannulated Screw 7.0mm x 16mm | 90mm | 031-70-90 | Ti031-70-90 |

| Cannulated Screw 7.0mm x 16mm | 95mm | 031-70-95 | Ti031-70-95 |

| Cannulated Screw 7.0mm x 16mm | 100mm | 031-70-100 | Ti031-70-100 |

| Cannulated Screw 7.0mm x 16mm | 105mm | 031-70-105 | Ti031-70-105 |

| Cannulated Screw 7.0mm x 16mm | 110mm | 031-70-110 | Ti031-70-110 |

| Cannulated Screw 7.0mm x 16mm | 115mm | 031-70-115 | Ti031-70-115 |

| Cannulated Screw 7.0mm x 16mm | 120mm | 031-70-120 | Ti031-70-120 |

| Cannulated Screw 7.0mm x 16mm | 125mm | 031-70-125 | Ti031-70-125 |

| Cannulated Screw 7.0mm x 16mm | 130mm | 031-70-130 | Ti031-70-130 |

Description |

|||

|

MODEL |

LENGTH |

S.S |

TITANIUM |

|

CANNULATED SCREW 7.0MM X 32MM THREAD |

40MM |

032-70-40 |

Ti032-70-40 |

|

45MM |

032-70-45 |

Ti032-70-45 |

|

|

50MM |

032-70-50 |

Ti032-70-50 |

|

|

55MM |

032-70-55 |

Ti032-70-55 |

|

|

60MM |

032-70-60 |

Ti032-70-60 |

|

|

65MM |

032-70-65 |

Ti032-70-65 |

|

|

70MM |

032-70-70 |

Ti032-70-70 |

|

|

75MM |

032-70-75 |

Ti032-70-75 |

|

|

80MM |

032-70-80 |

Ti032-70-80 |

|

|

85MM |

032-70-85 |

Ti032-70-85 |

|

|

90MM |

032-70-90 |

Ti032-70-90 |

|

|

95MM |

032-70-95 |

Ti032-70-95 |

|

|

100MM |

032-70-100 |

Ti032-70-100 |

|

|

105MM |

032-70-105 |

Ti032-70-105 |

|

|

110MM |

032-70-110 |

Ti032-70-110 |

|

|

115MM |

032-70-115 |

Ti032-70-115 |

|

|

120MM |

032-70-120 |

Ti032-70-120 |

|

|

125MM |

032-70-125 |

Ti032-70-125 |

|

|

130MM |

032-70-130 |

Ti032-70-130 |

Description |

|||

|

MODEL |

LENGTH |

S.S |

TITANIUM |

|

CANNULATED SCREW 7.0MM X FULL THREAD |

40MM |

033-70-40 |

Ti033-70-40 |

|

45MM |

033-70-45 |

Ti033-70-45 |

|

|

50MM |

033-70-50 |

Ti033-70-50 |

|

|

55MM |

033-70-55 |

Ti033-70-55 |

|

|

60MM |

033-70-60 |

Ti033-70-60 |

|

|

65MM |

033-70-65 |

Ti033-70-65 |

|

|

70MM |

033-70-70 |

Ti033-70-70 |

|

|

75MM |

033-70-75 |

Ti033-70-75 |

|

|

80MM |

033-70-80 |

Ti033-70-80 |

|

|

85MM |

033-70-85 |

Ti033-70-85 |

|

|

90MM |

033-70-90 |

Ti033-70-90 |

|

|

95MM |

033-70-95 |

Ti033-70-95 |

|

|

100MM |

033-70-100 |

Ti033-70-100 |

|

|

105MM |

033-70-105 |

Ti033-70-105 |

|

|

110MM |

033-70-110 |

Ti033-70-110 |

|

|

115MM |

033-70-115 |

Ti033-70-115 |

|

|

120MM |

033-70-120 |

Ti033-70-120 |

|

|

125MM |

033-70-125 |

Ti033-70-125 |

|

|

130MM |

033-70-130 |

Ti033-70-130 |

Description |

|||

|

MODEL |

LENGTH |

S.S |

TITANIUM |

|

CANNULATED SCREW 6.5MM X 16MM THREAD |

25MM |

128-65-25 |

Ti128-65-25 |

|

30MM |

128-65-30 |

Ti128-65-30 |

|

|

35MM |

128-65-35 |

Ti128-65-35 |

|

|

40MM |

128-65-40 |

Ti128-65-40 |

|

|

45MM |

128-65-45 |

Ti128-65-45 |

|

|

50MM |

128-65-50 |

Ti128-65-50 |

|

|

55MM |

128-65-55 |

Ti128-65-55 |

|

|

60MM |

128-65-60 |

Ti128-65-60 |

|

|

65MM |

128-65-65 |

Ti128-65-65 |

|

|

70MM |

128-65-70 |

Ti128-65-70 |

|

|

75MM |

128-65-75 |

Ti128-65-75 |

|

|

80MM |

128-65-80 |

Ti128-65-80 |

|

|

85MM |

128-65-85 |

Ti128-65-85 |

|

|

90MM |

128-65-90 |

Ti128-65-90 |

|

|

95MM |

128-65-95 |

Ti128-65-95 |

|

|

100MM |

128-65-100 |

Ti128-65-100 |

|

|

105MM |

128-65-105 |

Ti128-65-105 |

|

|

110MM |

128-65-110 |

Ti128-65-110 |

|

|

115MM |

128-65-115 |

Ti128-65-115 |

|

|

120MM |

128-65-120 |

Ti128-65-120 |

|

|

125MM |

128-65-125 |

Ti128-65-125 |

|

|

130MM |

128-65-130 |

Ti128-65-130 |

|

|

135MM |

128-65-135 |

Ti128-65-135 |

|

|

140MM |

128-65-140 |

Ti128-65-140 |

Description |

|||

|

MODEL |

LENGTH |

S.S |

TITANIUM |

|

CANNULATED SCREW 7.3MM X FULL THREAD |

40MM |

0330-73-40 |

Ti0330-73-40 |

|

45MM |

0330-73-45 |

Ti0330-73-45 |

|

|

50MM |

0330-73-50 |

Ti0330-73-50 |

|

|

55MM |

0330-73-55 |

Ti0330-73-55 |

|

|

60MM |

0330-73-60 |

Ti0330-73-60 |

|

|

65MM |

0330-73-65 |

Ti0330-73-65 |

|

|

70MM |

0330-73-70 |

Ti0330-73-70 |

|

|

75MM |

0330-73-75 |

Ti0330-73-75 |

|

|

80MM |

0330-73-80 |

Ti0330-73-80 |

|

|

85MM |

0330-73-85 |

Ti0330-73-85 |

|

|

90MM |

0330-73-90 |

Ti0330-73-90 |

|

|

95MM |

0330-73-95 |

Ti0330-73-95 |

|

|

100MM |

0330-73-100 |

Ti0330-73-100 |

|

|

105MM |

0330-73-105 |

Ti0330-73-105 |

|

|

110MM |

0330-73-110 |

Ti0330-73-110 |

|

|

115MM |

0330-73-115 |

Ti0330-73-115 |

|

|

120MM |

0330-73-120 |

Ti0330-73-120 |

|

|

125MM |

0330-73-125 |

Ti0330-73-125 |

|

|

130MM |

0330-73-130 |

Ti0330-73-130 |

FAQ: Suppliers of Bone Screws in India

Q1: What are bone screws, and why are they important?

Bone screws are medical implants used in orthopedic surgeries to fix broken or fractured bones. They provide stability, promote proper alignment, and support the healing process.

Q2: Who are the top suppliers of bone screws in India?

Some leading suppliers of bone screws in India include:

- ACE Osteomedica

- Siora Surgicals

- GPC Medical Ltd.

- Narang Medical

These companies specialize in high-quality bone screws and other orthopedic implants.

Q3: What materials are used for bone screws?

Bone screws are typically made from medical-grade materials such as:

- Stainless steel: Durable and affordable.

- Titanium: Lightweight, corrosion-resistant, and biocompatible.

Q4: What types of bone screws are available?

Common types of bone screws include:

- Cortical screws: Used for dense bone areas.

- Cancellous screws: Designed for spongy bone.

- Cannulated screws: Ideal for minimally invasive surgeries.

Q5: How can I find reliable supplkiers of bone screws in India?

To find reliable suppliers:

- Research online: Look for certified suppliers with ISO and CE certifications.

- Check reviews: Read testimonials and feedback from healthcare professionals.

- Visit trade shows: Medical expos often showcase top suppliers.

Q6: Are Indian bone screw suppliers globally recognized?

Yes, many Indian suppliers are recognized worldwide for their quality and affordability. They adhere to international standards such as ISO 13485 and CE marking.

Q7: Can bone screws be customized?

Most suppliers in India offer customization options based on surgical requirements. Surgeons can specify the size, material, and thread design.

Q8: What quality standards do Indian suppliers follow?

Indian suppliers follow strict quality standards, including:

- ISO 13485 certification

- CE marking compliance

- Adherence to GMP (Good supplying Practices)

Q9: Are bone screws exported from India?

Yes, India exports bone screws to several countries due to their high quality and cost-effectiveness. The demand for Indian orthopedic implants is steadily growing globally.

Q10: How can I contact ACE Osteomedica for bone screws?

You can reach out to ACE Osteomedica, a leading supplier, through their official website: ACE Osteomedica. They offer a wide range of bone screws and other orthopedic implants.